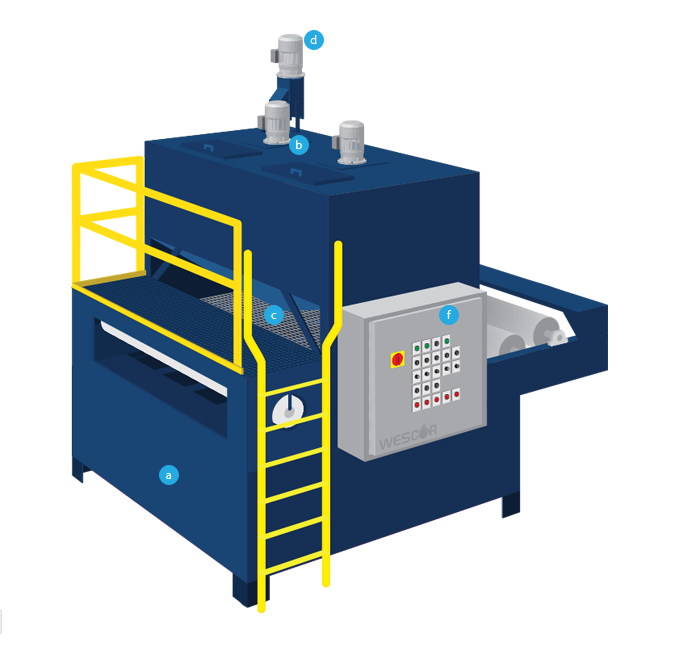

Batch Treatment System

Batch processing generally consists of a treatment tank, agitators, chemical feed, pumping system, solids separation & filtration. This system may be configured to use dry or liquid chemistry. We have several turn-key configurations. A variety of equipment models are available which provides attractive economics for both the small and midsized users. Dependant of plant preferences; filtration type, chemical feed and manual or automation control packages are offered.

Oily Wastewater

Spent coolants & lubricants, parts washing water, vibratory finishing effluent, floor scrubber/mop buckets, emulsion splitting, pit/trench water, storm water/runoff

Food Production

CIP / Sanitization wastewater, food washing & preparation wastewater

Metal Finishing

Wash booth effluent, vibratory waste, phosphate treatment

General Industry

Paint water waste, equipment wash water, production tank clean-out

Printing & Corrugated Industry

Starch, metals, inks and adhesives

Transportation

Heavy equipment wash water, tanker truck wash-out, turf care equipment