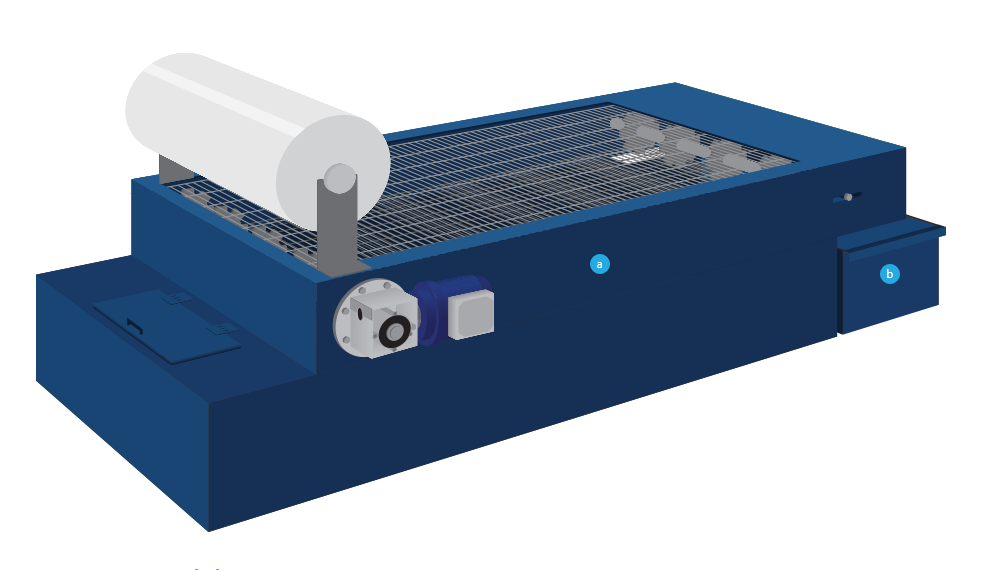

Gravity Filter Bed

Our Gravity Filter Bed is designed for continuous filtration applications capable of removing moderate to high levels of contamination. Roll filter media is available in numerous material types, porosity and weights to meet a wide range of fluid filtration needs.

Standard:

a

Carbon or stainless steel construction

b

Filter cake bin

c

Sludge dewatering roller

d

Capacities up to 1,000 L/min

e

Filtrate pump

Gravity filter beds are designed for continuous filtration applications capable of removing moderate to high levels of contamination. Fluid is pumped onto the filter bed and drains by gravity through the filter media. Solids are captured by the filter media, while filtered fluid collects in the lower reservoir.

The filter bed consists of a stainless steel conveyor with level control. As the filter media removes solids, the material slowly becomes restricted and the fluid level rises on the filter. When the fluid level reaches the level control sensor, the conveyor drive motor is activated which transports the used filter media and collected solids into a solids hopper. Clean filter media is indexed allowing the filtration process to continue uninterrupted.

Roll filter media is available in numerous material types, porosity and weights to meet a wide range of fluid filtration needs. The low cost of roll filter media provides a significant cost advantage over pressure and self cleaning filters.