Chemical Feed Equipment

Effective chemical preparation and proper introduction of chemical into the wastestream is essential in all waste treatment processes. Accurate and reliable chemical dosing and mixing ensures predictable results from the downstream processes and helps to ensure maximum yield from the chemicals being applied.

WESCOR provides chemical preparation and metering equipment for dry and liquid chemistries including:

Liquid Polymer Makedown

Liquid polymer makedown equipment mixes concentrated liquid polymer with water to produce a dilute polymer solution which is applied to the wastewater treatment process. Concentrated polymer must be properly handled through the mixing process in order to become properly activated and achieve a consistent final product. Concentrated polymer has a tendency to ‘gel’, or produce ‘fisheyes’ if appropriate mixing energy is not applied. Gelled polymer caused numerous difficulties to downstream pumps and the wastewater treatment process. WESCOR designs polymer makedown equipment for proper activation of neat polymer in several configurations including: manual or automated batch solution preparation, storage and transfer equipment or continuous feed systems.

Features: Polymer makedown, aging tank, neat polymer pump, solution transfer pump, level controls, tank agitator

Dry Polymer Makedown

Dry polymer makedown: Dry polymers are often the material of choice for many waste treatment plants due to ease of handling, product availability and economics. Dry polymers have unique activation requirements. WESCOR dry polymer systems provide the proper polymer/water interface in order to ensure proper blending, followed by sufficient mixing during the aging process to achieve complete polymer activation.

Features: Volumetric feeder, makedown chamber, aging tank, solution transfer pump, level controls, tank agitator

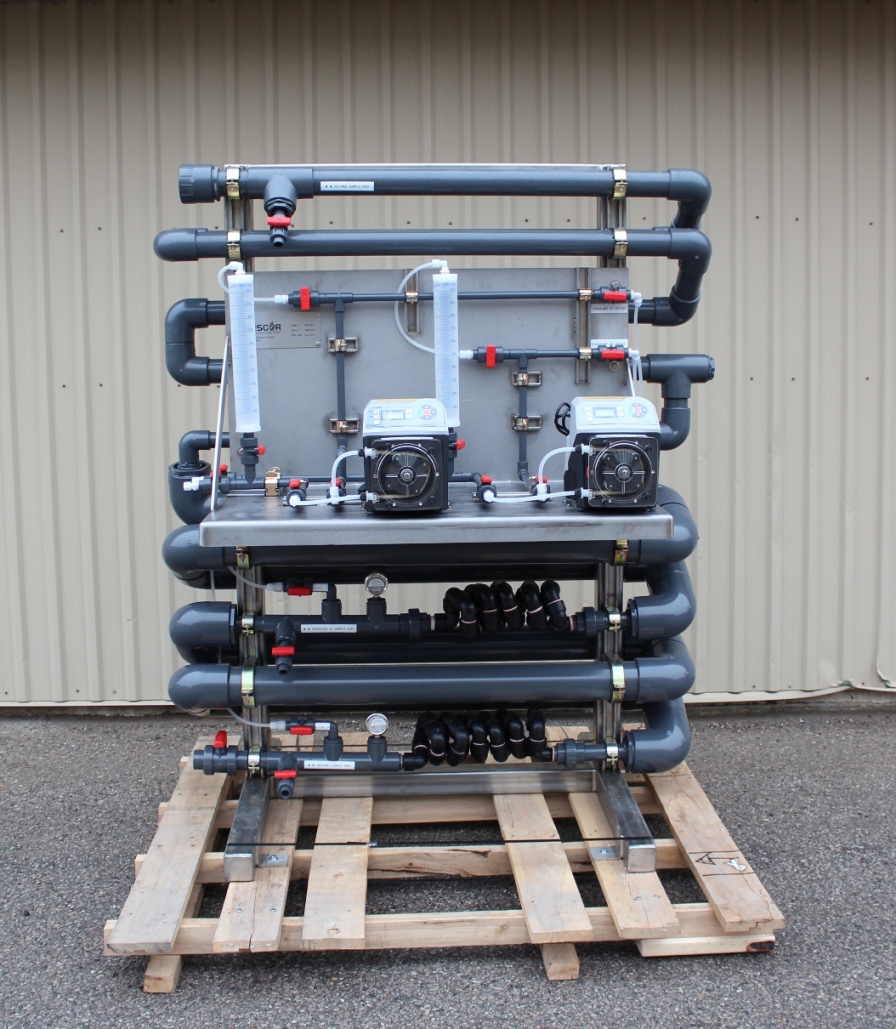

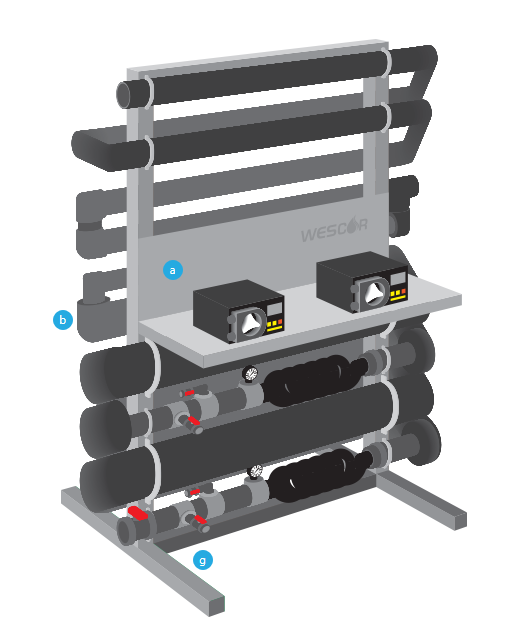

Inline Mixing Systems

WESCOR’s plug flow pipe flocculators and inline chemical mixing systems are designed for optimal chemical mixing and retention time to promote ideal coagulation and flocculation. Inline chemical injection and mixing allows for sequential introduction of multiple treatment chemistries. Mixing systems design characteristics allow for closely defined mixing characteristics to facilitate uniform floc growth.

Features: Multiple mixing zones, no additional energy input, sample ports, multiple injection points

Dry Chemical Feeder

Dry Chemical Volumetric Feeder: WESCOR’s dry chemical feed systems are available in a variety of configurations suitable for small to mid-sized chemical conveying requirements. Volumetric feeders are capable of conveying powders, granular, pellets, flakes or other free flowing materials at a consistent rate within 1-2% accuracy.

Features: Pipe flocculators, dry polymer solution makedown, chemical day tanks & mixing, dry chemical volumetric feeders, inline chemical mixing