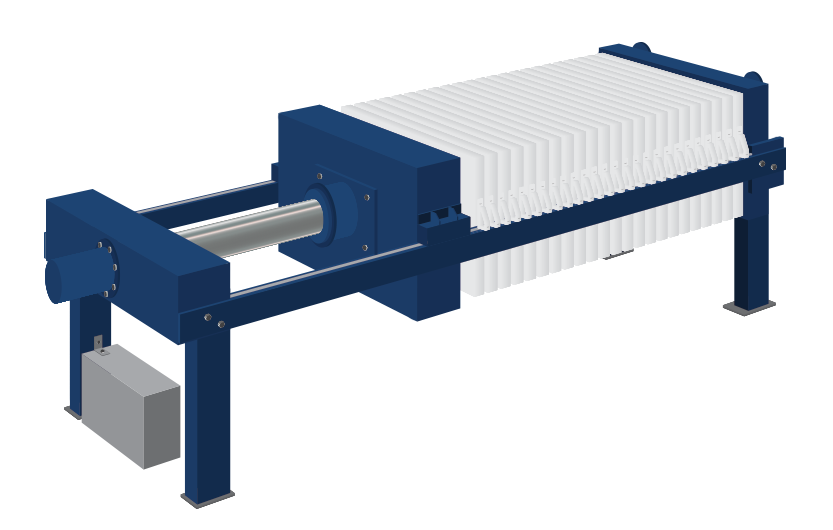

Filter Press

The filter press is constructed of a structural steel frame which supports and pressurizes the filter plates. The plates utilize a re-usable filter cloth which is available in a variety of mesh sizes. The cloths are fixed within the vertical plate structure. A number of plates are organized beside on another and held tightly together by a hydraulic ram. The surface of each plate is recessed which creates chambers between one another. Liquid to be filtered is pumped into the press and passes through the filter cloth. Solids are captured on the cloth and gradually form a filter cake within each of the recessed chambers. As the filter press begins to fill with solids the pump pressure is increased resulting in a greater degree of dewatering of the sludge cake. When the filter press is full, remaining water is purged from the filter cake by a compressed air blown-down cycle.