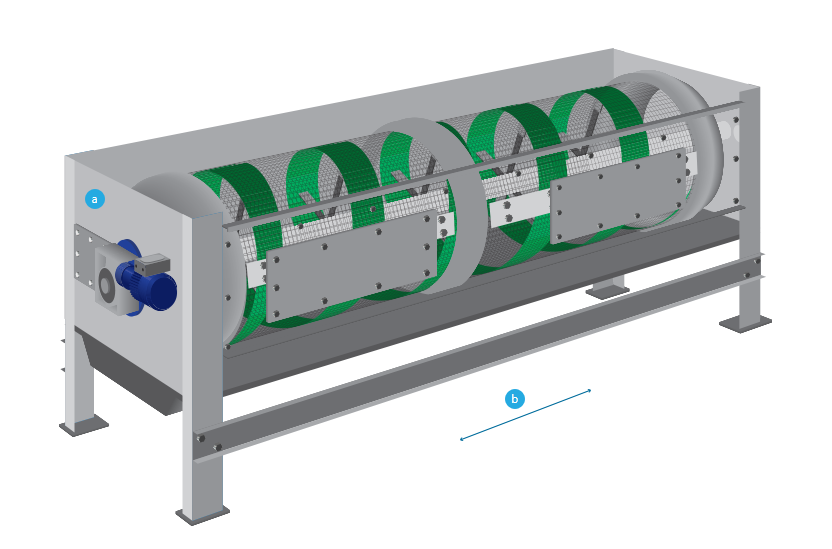

Rotating Drum Thickener

Slurry enters the RDT, and is distributed across the entry zone of the horizontal drum which is constructed of a structural stainless steel frame covered in fabric filtration panels. As the drum rotates slurry cascades across the filter panels. Water drains through the panels resulting in a concentration of solids along the drum. A spiral flight within the drum moves the slurry along the drums length. Solids discharge by gravity from the end of the drum.

The drum operates continuously and automatically. The adjustable speed gear drive permits adjustment to the dewatering rate & process optimization by modifying the drum rotation speed. The simple, low maintenance design requires little supervision and produces consistent treatment results. A spray wash system cleans the filter panels on either an intermittent or continuous basis. The system is entirely enclosed containing odors & misting.

The RDT can be integrated into wastewater treatment systems to improve operating efficiencies of existing technologies. WESCOR’s VFOLD belt filter press is designed to mate with the RDT creating a complete dewatering package in a 4′ x 13′ footprint. The RDT & VFOLD combination can be configured to act as a complete wastewater treatment system eliminating the need for an upstream Clarifier of Dissolved Air Flotation unit in some applications